Engineering

At DCI, our strength is designing turnkey supply chain systems for distribution centers. Because companies have unique manufacturing, processing or distribution requirements, the experienced DCI team will work with you to engineer a system that meets the requirements of your specific environment. Whether we are updating an existing system or designing for a greenfield facility, our engineering methodology will maximize the operational performance of your system.

DCI engineering services include:

- Analysis of issues to develop long-term solutions with high ROI

- Design & fabrication of custom equipment

- Assistance in warehouse / plant layouts for a variety of industries including wholesale, retail, food processing, manufacturing, packaging and automotive

- Front end engineering to provide a more accurate assessment of your needs

- Integration of a variety of ideas and equipment, no matter how large, small or complex your needs may be

- Mechanical drawings in 2D and 3D for layouts and custom components to meet stringent specifications

- Preparation of Functional Design Documents

- Electrical engineering of components and full panels that meet all required codes

Experienced, educated and customer focused, our engineering staff will provide you with a first-class design and documentation for each project. Every project is thoroughly designed to meet your needs and to be cost effective. Our front end engineering methodology enables us to identify and resolve problems with a system before installation – not after.

The DCI Engineering team provides technical support from Proposal to As-Built documentation, and beyond. We can provide your staff with:

- Proposal Drawings and Calculations

- Approval Drawings and Details

- Control Design Needs Analysis and Build

- MCP Design and Layout

- Fabrication Design Drawings, Details and Specifications

- PC and PLC Programming Documentation

- Complete Installation Layouts

- Electrical Wiring Schematics

- Structural Calculations and Point Load Details

- Network Layout and Design

- Seismic Calculations

- Stamped PE Documentation

- As-Built Drawings, Schedules and Manuals

Controls

Every day, DC managers are asked to make improvements in their system in less time with fewer resources. Establishing the proper control system that integrates with your organization’s IT system can help you improve productivity, reduce errors and provide management with valuable information on system performance. DCI offers a completely engineered control system that integrates all aspects of your system including:

- Warehouse Management and Control Systems

- Pick Optimization

- PC and PLC Based Systems

- Barcode Scanning

- Label/Printer Application Technologies

- VPN Remote Support

- Graphical User Interface

- Report Generation

- Emergency Shut-Down

System Studies / ROI

System Capacity Studies

Whether you are preparing to break ground on a new project or expanding your current facility, a system capacity study can help you plan the conceptual design and space requirements that will support your future growth.

DCI can help your company identify its facility needs and discuss the various technology options available in order to develop an overall strategic plan for your company’s growth.

System Optimization

The efficiency of any material handling system depends on the speed, accuracy and dependability of its equipment. In order to optimize the cost of production and the function of the system itself, the system should be carefully designed to balance throughput, ease of use and return on investment.

System Optimization Consulting explores several factors when trying to improve the performance of your system. Maintaining your conveyor equipment is critical to optimizing your system. Regular scheduled maintenance can help keep your facility operational with little or no downtime. In addition, paying special attention to performance testing, controls, utilization of energy, product selection and employee workstations will allow your company to reach new levels of productivity.

DCI is ready to assist you with optimizing your system to minimize operational costs and maximize productivity. DCI can provide you with turnkey solutions to keep your business moving forward.

Cost/ROI Analysis

An important step in evaluating the purchase of a conveyor system is to analyze initial cost, total cost of ownership (TCO), maintenance requirements, noise levels, energy consumption and productivity. This analysis can be a daunting task, and DCI is ready to assist you with a Return on Investment Analysis. We can help you answer the tough questions – How will energy costs affect the long-term ROI? What are my expected maintenance costs? How long will the equipment last? Determining these answers will help you evaluate each system option and choose the best one to meet your needs.

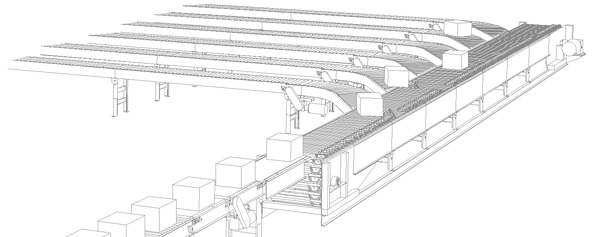

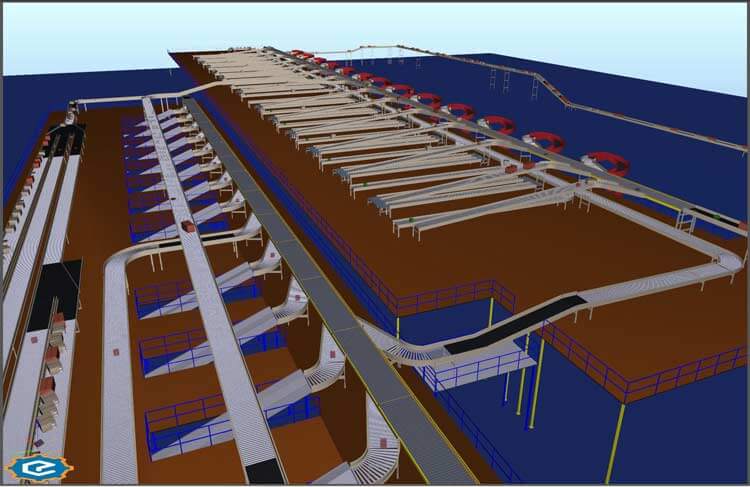

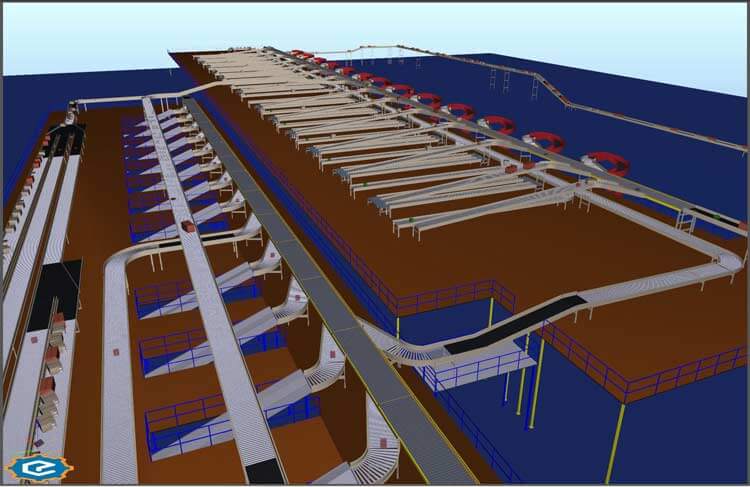

3D Layouts & Simulations

Utilizing advanced design technology, our design team is capable of producing 3D layouts and simulations for each area of your conveyor system. We can accurately model and demonstrate your proposed system to help identify potential problem areas and to rectify these during the design phase. The 3D layout can be developed into an artistic rendering to provide you with a significantly more detailed view of your system. Simulations provide visualization of how your system will work, allowing you to see everything in motion before it is installed.

Structures / Racking

Should the design of your distribution center require the need for more specialized internal structures, DCI is equipped to design those for you as well. Whether your facility or system requires racking for extra storage space, mezzanines to utilize vertical space and increase your facilities workspace, or staircases or ladders to safely get places quickly or access maintenance areas, we have the experience and resources to accomplish your goals. A few of the structures we can help with are:

- Mezzanines

- Platforms

- Pick Modules

- Rack

- Stairs

- Handrails

- Crossovers

Fabrication

DCI understands that many system objectives are not always met by standard “off-the-shelf” components. In order to meet custom needs, DCI designs and fabricates a broad spectrum of custom built “special” equipment and solutions including structures, special devices and accessories.